Hands On

With an ESP8266 and a few components, you can put together your own robot arm.

Lead Image © realmccoy, 123RF.com

With an ESP8266 and a few components, you can put together your own robot arm.

The ESP8266 is an extremely versatile chip. One of its many uses includes controlling servomotors. By way of example, during one of our workshop sessions we took some circuit boards and put together a robot arm, which in this project will attempt to solve the "Tower of Hanoi" puzzle (See box out: Until Doomsday)

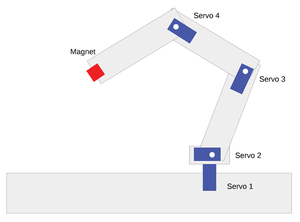

A rudimentary robot arm requires at least four planes of movement: one at the very base to rotate the robot itself, and three in the arm to move it to different positions. Figure 1 shows a simplified diagram for this model.

Figure 1: This plan for a robot arm is extremely simplified but shows the basic components you need to make it moveable.

Figure 1: This plan for a robot arm is extremely simplified but shows the basic components you need to make it moveable.

[...]

Pages: 8

Price $15.99

(incl. VAT)